TECHNICAL GARMENTS

In one of my study projects, I focused on the process between the sketch and the final product, where all the real technical work happens and garment technical knowledge comes into play.

This technical garment process serves as a crucial bridge between fashion design and product development, translating creative concepts into practical, production-ready garments by focusing on fit, construction, cost, and functionality.

My role involved turning ideas into production-ready garments by ensuring perfect fit, selecting appropriate construction methods, researching production costs, and making sure every detail was practical and worked effectively.

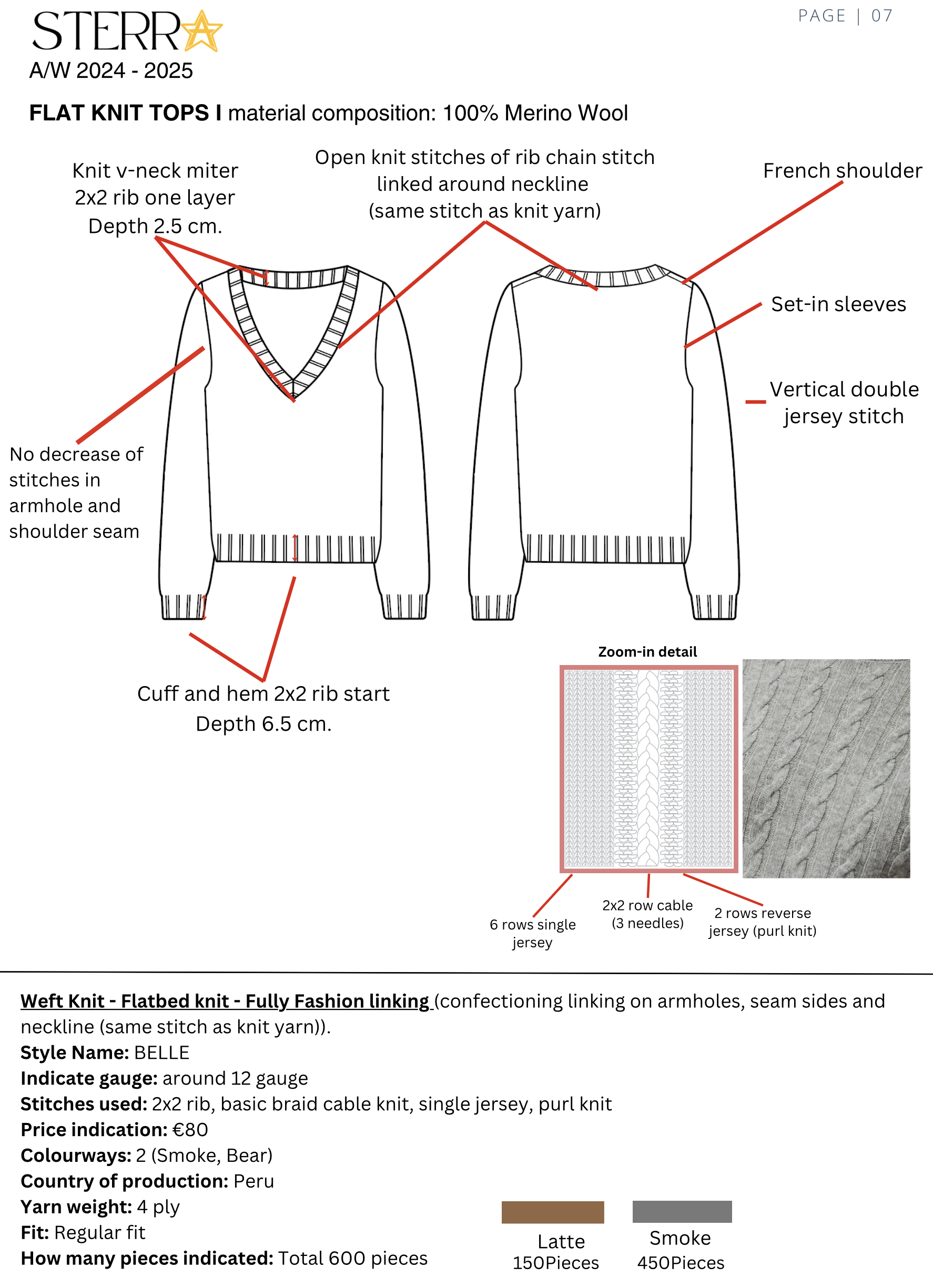

KNITTING ANALYSIS

During my studies and hands-on experience, I got to really dive into understanding knitted fabrics—how their structure, yarn, and stitching all come together to create something that not only looks good but performs well too. I learned to pay attention to details like fabric stretch, durability, and how dense or loose the knit is, because these little things make a big difference in the final product.

This experience helped me see how important it is to get these technical details right to create knitwear that fits comfortably and works for its purpose, whether it’s fashion-forward pieces or activewear. I also learned how this knowledge plays a key role in choosing the right materials, production methods, and finishing touches to make sure the garment lasts and feels great to wear.

TEXTILE ANALYSIS

Through fabric testing, like colorfastness to rubbing, dry-cleaning, and hot pressing, I developed a strong understanding of how to evaluate textile quality and durability while ensuring compliance with ISO standards for everyday garments. I also researched the chemicals used in production, their restrictions, and how they impact product quality.

This experience gave me valuable insight into quality assurance, performance evaluation, consumer safety, regulatory compliance, and ways to improve production processes for better and more sustainable outcomes.

MERCHANDISE PLAN

In my Buyer project, I was responsible for merchandise planning—strategically selecting products, determining quantities, and scheduling launches to meet customer demand while managing inventory efficiently. I also contributed to sales planning by setting sales targets, identifying key markets, and developing pricing and promotional strategies to drive revenue.

This project gave me hands-on experience in aligning merchandise and sales plans to ensure the right products reached the right customers at the right time, supporting both customer satisfaction and business growth.